Vinyl Glove Boxes

These flexible vinyl glove boxes are a simple low-cost alternative to rigid glove boxes for sealed environments or simple containment applications. Equipped with gas inlet and automatic pressure relief system the vinyl chamber can easily create a low oxygen or dry gas environment.

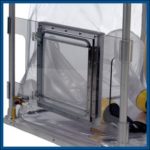

- PVC construction — Made of heavy-duty, flexible PVC mounted on a rigid base with aluminum support frame.

- Radio-frequency welded seams — For a one-piece bag that will withstand years of service.

- Optically clear vinyl — Increases operator vision

- Flexible gloves and ports for increased operator ergonomics

- Custom sizes and configurations

More than 20 different options are also available to allow you to adapt these simple unit that can be purged with any inert gas through the gas inlet valve and the automatic pressure relief valve, standard on all vinyl glove boxes.

Aluminum glove boxes and rigid polymer glove boxes are also available.

Vinyl Glove Box Details

All Basic Vinyl Glove Boxes are supplied with the following:

- Latex gloves in size large (other sizes available on request*)

- Inlet ball valve

- Pressure relief system (removable for simple containment operations)

- Side door or optional airlock transfer chamber connection

- Aluminum support frame with padded base

- Internal 6-outlet power supply

- Two feed-thru adapters with rubber stopper (1.5″/3.8 cm diameter)

- Round entry port (20″/50.8 cm)

* The latex gloves are placed over a plastic cuff and then placed in the permanently attached sleeves and taped in place. This system provides a means of replacing damaged gloves. Additional glove ports can be ordered mounted in most positions if requested at the time of purchase.

Construction

The glove box front is made of 20 mil pressed polished clear vinyl with 40 mil vinyl bottom extending 2″ (51 mm) up on all sides. It is mounted on a 3/4″ (19 mm) plywood base covered with a 1/4″ (6 mm) foam pad and heavy vinyl. A 1″ (25 mm) aluminum tubular frame supports the glove box. All glove boxes come with a large equipment entry on the rear of the unit. This entrance consists of a 20″ (50 cm) entry cap that is taped in place after installing large equipment in the glove box.

- Glove ports, 10″ x 13″ oval opening (25 x 33 cm) on 19″ (48 cm) centers, are constructed of a special highly flexible vinyl frosted to prevent cracking and gas leakage at bend points.

- Two 1.5″ (38 mm) I.D. feed-thrus are attached for wiring, tubing, or cord input. (Additional feed-thrus may be ordered at the time of purchase.)

Documents provided here for reference. Contact us with your specific questions or request for customizations.

In addition to R&D and university research laboratory applications, Coy controlled environment glove boxes have found use in other glove box applications including:

- Micro welding

- Dry atmosphere storage

- Electronic equipment assembly

- Clean room glove box

- Containment glove box

- Dry packaging

- Controlled humidity applications

- Chemical mixing

- Inert gas purge

- Oxygen control

- Humidity control

- Dry weighing

Below are common accessories associated with the Coy Vinyl Basic Glove Boxes.

- Airlock for sample transfer

- Atmosphere filtration system (HEPA)

- Oxygen monitor or control system

- Humidity monitor or control system

- CO2 control and monitoring system

- Desiccant drying system

- Feed-thru ports (for cords and tubing pass thru to chamber interior)

- Custom sizing (contact Coy for details)

- Flow meters for precise gas purge control

- Microscope port

- Temperature control options (chiller &/or heaters)